Autonomous Mobile Robots: Choosing the Right AMR Robot for Your Site

During the last decades, Autonomous Mobile Robots (AMRs) have changed the game in industries, warehouses, and healthcare, as these self-guided machines offer efficiency boosts, cost-cutting, and a safety upgrade for an ever-increasing number of companies out there.

In this thorough guide, we’re breaking down the nitty-gritty of why choosing the right AMR for your site matters. From squeezing through tight spaces to syncing seamlessly with your setup, it is all about picking the right tech for the job. Keep reading to discover how integrating the right AMR in your workflow can boost your business!

Understanding Autonomous Mobile Robots

Let’s start with the basics: what are Autonomous Mobile Robots exactly? An AMR is a robot capable of navigating its surrounding environment without human intervention. AMRs normally count on an array of sophisticated sensors that enable them to understand and interpret their environment, which helps them to perform their task in the most efficient manner and path possible, navigating around fixed obstructions and avoiding any obstacles in their way.

Autonomous Mobile Robots (AMRs) encompass various types tailored for specific tasks:

- AGVs (Automated Guided Vehicles) are those who follow predefined paths, while mobile robots navigate dynamically using sensors and AI.

- Collaborative robots (Cobots) work alongside humans, enhancing teamwork.

- Swarm robots operate collectively, sharing information for efficient coordination.

- Delivery robots autonomously transport goods within defined spaces.

- Service robots assist in tasks like cleaning, security, or customer service.

Each AMR type caters to unique applications, offering flexibility and innovation in automation solutions.

The Key Benefits of AMR Robots

Autonomous Mobile Robots have become pivotal in transforming various industries, offering a trifecta of advantages: increased efficiency, reduced operational costs, and improved safety. In manufacturing, AMRs streamline material handling, optimizing workflows. A case in point is Amazon’s fulfillment centers, where Kiva robots autonomously transport shelves to workers, increasing order processing speed and minimizing human travel.

Operational cost reduction is a significant benefit across sectors. In logistics, AMRs contribute to warehouse efficiency by automating inventory management and order fulfillment, curbing labor costs associated with repetitive tasks. The result is a leaner, more cost-effective supply chain.

AMRs also bolster safety in environments traditionally prone to risks for human operators. In industrial environments, robot dogs like Keyper autonomously perform inspection rounds, carrying out tasks such as instrument reading, gas leakage detection, and incident reporting while minimizing human exposure to potentially hazardous situations and increasing facility monitoring.

In summary, the integration of AMRs brings tangible benefits to a vast array of industries. The seamless collaboration between humans and robots amplifies efficiency, cuts operational costs, and creates safer work environments, fostering a new era of productivity and workplace well-being.

Factors to Consider When Choosing an AMR Robot

Payload Capacity

When choosing an Autonomous Mobile Robot its payload capacity, or the maximum weight it can carry, can be a critical factor depending on its intended application. Determining the right payload is vital for optimal performance in specific applications. For instance, in manufacturing, where AMRs transport materials, selecting a capacity exceeding the average load ensures flexibility to accommodate varying demands. Conversely, in healthcare settings using AMRs for medication delivery, a lower payload may be suitable. In essence, tailoring the payload capacity to the specific requirements of the task at hand ensures efficiency and prevents unnecessary strain on the AMR, maximizing its utility across diverse industries.

Navigation Technology

AMRs employ various navigation technologies, including LiDAR (Light Detection and Ranging) and SLAM (Simultaneous Localization and Mapping). LIDAR uses laser beams to measure distances, offering accurate mapping and obstacle detection. SLAM combines sensors to create maps and locate the robot in real time, providing flexibility but requiring computational power.

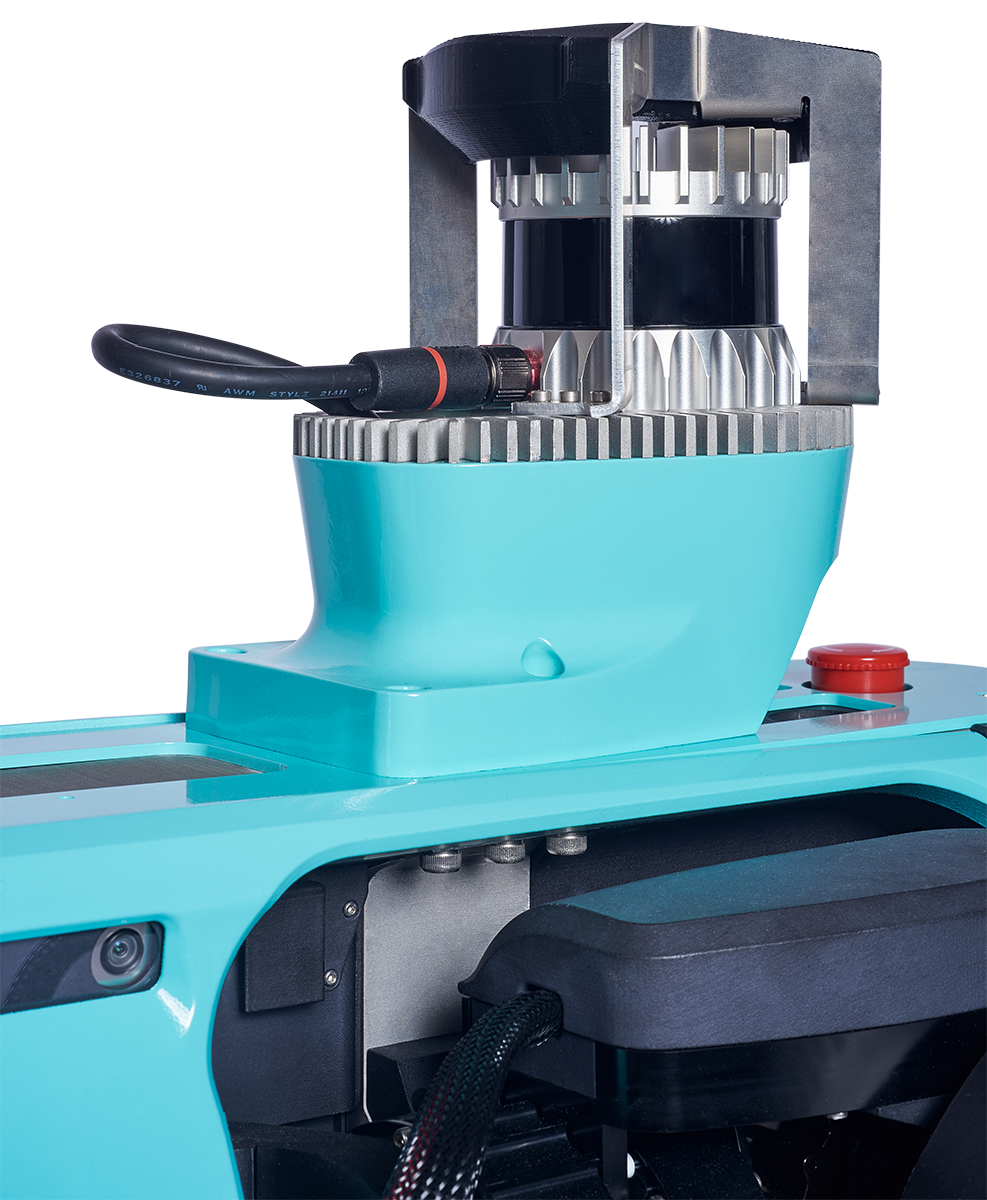

The choice of navigation technology profoundly impacts AMR performance. LIDAR (pictured here) excels in precision, ideal for intricate environments, but may strain budgets. SLAM offers adaptability but demands computational resources. The decision hinges on specific operational needs. In dynamic settings like warehouses, where adaptability is crucial, SLAM might shine. Alternatively, in structured environments with a focus on precision, LIDAR could be the preferred choice, underscoring the importance of aligning navigation tech with application requirements for optimal AMR performance.

Customization Options for Autonomous Mobile Robots

Customization in Autonomous Mobile Robots is pivotal for aligning robotic solutions with diverse business needs. Businesses can tailor AMRs by adjusting parameters such as payload capacity, navigation algorithms, and sensor configurations. In manufacturing, customization allows integration with existing production lines, optimizing material flow. For instance, companies like Flexiv deploy customizable robotic arms for precise tasks in electronics manufacturing.

In logistics, AMR customization ensures adaptability to varying warehouse layouts and inventory management systems. Amazon’s Kiva robots, already mentioned in this article, showcase successful customization, dynamically adjusting to the e-commerce multinational’s evolving operational needs. Tailoring AMRs to specific industries enhances efficiency, minimizes costs, and maximizes the robotic system’s contribution to the overall workflow, exemplifying the crucial role of customization in unlocking the full potential of autonomous robotics.

Selecting the Right AMR Robot for Your Site

Selecting the right AMR for your site requires a meticulous, tailored approach. Identify your specific needs by evaluating factors already mentioned such as payload capacity, navigation requirements, and compatibility with existing infrastructure.

There’s no universal solution; each industry and workspace demands a unique fit. Consider the intricacies of your operational environment, workflow, and objectives to pinpoint the AMR features crucial for success. A customized approach ensures that the chosen robot aligns precisely with your site’s requirements, optimizing efficiency and performance.

Practical Implementations

Logistics giant DHL implemented AMRs for warehouse tasks, improving accuracy and speeding up inventory management. In Spain, one of the country’s biggest chemical plants has implemented Keyper robot dogs to perform autonomous inspection rounds, reducing human exposure to potentially hazardous environments, effectively offering predictive maintenance by detecting incidences in equipment and contributing to significantly reducing shutdown time.

These case studies illustrate that AMR integration brings positive outcomes, such as improved productivity, reduced operational costs, and enhanced safety. Key lessons include the importance of aligning AMR capabilities with specific industry needs and the need for seamless integration into existing workflows for maximum impact.

Choosing the right AMR is pivotal for success in automation. Don’t underestimate the impact of a tailored solution on efficiency and productivity. Take the next step: consult experts and manufacturers to align your site’s unique needs with the ideal AMR.

If you would like to discover more about how Keyper can contribute to boosting efficiency and safety in your industrial sites, take a look at our Technology page or schedule a demo with our team!