Advanced Autonomous Navigation: The Technology Behind Industrial Robotics

Autonomous robots have been populating our daily lives for years. Most of us, for example, have in our homes robotic vacuum cleaners with the ability to autonomously navigate their environment and make decisions based on what they encounter in their paths as they complete their cleaning missions.

However, when we look at the industrial sector, this type of robot still has a relatively low penetration, despite the tremendous benefits they can offer in terms of increased safety and productivity. In this article, we will explore the advanced technology behind autonomous navigation systems and their relevance to the industrial sector.

Understanding Autonomous Robots

We define autonomy as the ability to make independent decisions. Autonomous robots, then, are those who can make their own decisions and perform actions accordingly. A truly autonomous robot is an intelligent machine that can perceive its environment, make decisions based on what it perceives, and then take action within that environment without human control or intervention. These decision-based actions include, for example, basic tasks like starting, stopping, and maneuvering around obstacles that are in their way.

We talk about autonomous navigation when we refer specifically to the robot’s ability to autonomously define a trajectory through the environment to reach a specified location, dealing with any possible unexpected obstacles.

Just like robotic vacuum cleaners, autonomous mobile robots developed for the industrial sector, such as Keyper, possess a set of sensors that allow them to perceive their environment, decide a course of action based on these perceptions, and then take appropriate action without human interference. Thanks to these abilities, AMRs are already transforming how certain tasks, such as site inspection and monitoring, are being performed in industrial environments.

Key Components of Autonomous Navigation

Before we discuss their industrial applications, let’s look at the essential components and sensors used in autonomous navigation systems, which can be divided into three key concepts: perception, decision, and actuation.

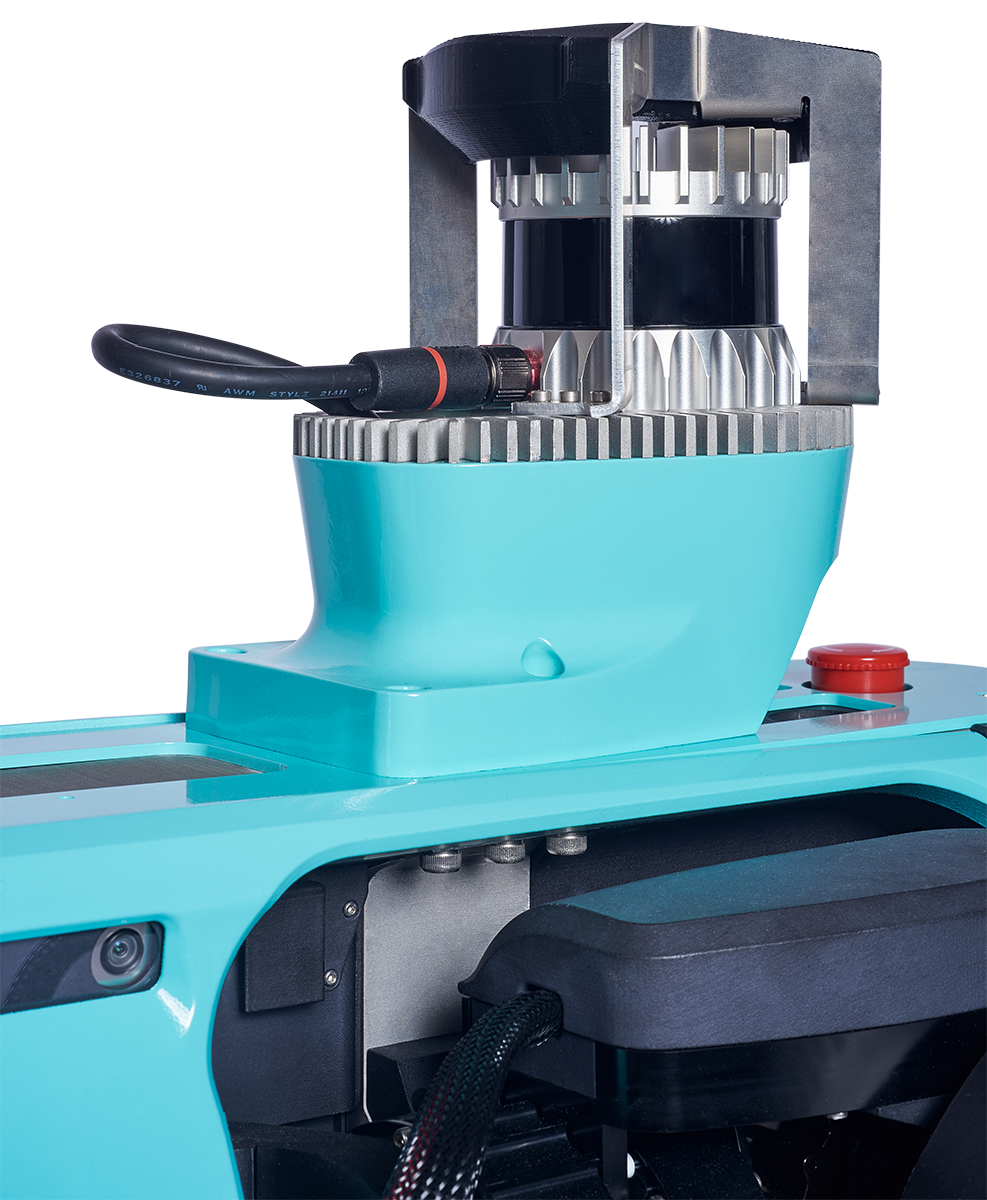

- Perception: Autonomous robots sense their environment through a variety of technologies including laser scanners, radars, and spectrometers. High-level robots, such as Keyper, use complex sensors like cameras, LiDARs, microphones, thermal cameras, and explosimeters, which, combined with image-recognition software, allow the robot to identify and categorize the objects they see as well as the conditions of their environment, and make real-time decisions. AMRs also offer unique mapping capabilities: not only will they map the entire facility, but they also regularly update that map with the most efficient routes possible.

- Decision: Just like the human brain makes most of our decisions, the computer acting as the “brain” of a robot makes decisions based on what its mission is and what information it receives along the way from all the sensors previously mentioned. However, robots also count on a “neurological” system, which operates faster and with higher authority than the computer that is executing a mission plan. This is how the robot can decide to stop if it notices an obstacle in its way or if its emergency stop button is pressed.

- Actuation: The robot’s actuators would be the equivalent to human muscles, and work through motors that convert energy into movement. That’s the system that allows robot dogs such as Keyper to walk, sit, or climb stairs and slopes.

Advanced Technologies in Autonomous Robots

Let’s take a closer look at some of the technological advancements we can find nowadays in autonomous robots:

- LiDAR: also known as “light detection and ranging,” LiDAR is a remote sensing method that uses light in the form of a pulsed laser to measure ranges (variable distances). This 360-degree-looking solution uses those light pulses to generate precise, three-dimensional information about the robot’s environment.

- Computer vision: this technology is what allows autonomous robots to extract information from images, which can come from a variety of sources, such as cameras and the previously mentioned LiDAR sensors. Thanks to this technology, AMRs can perform tasks such as object detection and recognition, event detection, or video tracking. In the case of Keyper, its advanced computer vision combined with AI allows it to, for example, read gauges and meters and detect whether their values can be determined as “normal”, or an incidence needs to be immediately reported.

- Machine learning: this technology uses algorithms to allow the robot to learn from data and generalize to unseen data, and thus perform tasks autonomously, without explicit instructions.

Real-World Applications

While autonomous mobile robots have a variety of applications, on this occasion we are going to focus on one of the areas where they add more value to the industrial sector: inspection and maintenance rounds.

In industries such as the chemical one, traditional inspection tasks have been carried out by human personnel, entailing great risks for the staff in case of, for example, gas leaks. However, the development of AMRs such as Keyper, specifically designed to perform inspection and monitoring rounds more safely and efficiently, is revolutionizing the status quo one industrial plant at a time.

Let’s look at it more closely: up until now, the only way in which a chemical company could keep their facilities under control was to have one (or several) human operators performing regular rounds across each plant, and visually reviewing all key meters and gauges to check their data stayed within normal parameters. But gas leaks –a very dangerous situation- are not rare in this kind of installation, and they would go undetected until the operator walks past the affected area and measures the gas levels in the air, with great risk to their safety and that of their coworkers.

Autonomous robots for industrial inspections, such as Keyper, however, can autonomously perform this kind of round and complete tasks such as reading meters and gauges, detecting any kind of incidence through their cameras, as well as their thermal, acoustic, and gas detectors. Not only do they eliminate the need to place human operators in potentially dangerous situations, but they can perform more frequent rounds, ensuring the facilities are always under control and any potential incident gets reported immediately, contributing to increasing the plant’s productivity and diminishing significantly the need to shut down production.

Autonomous navigation, then, has become essential for robots to move from the theoretical plan to adding value in a real-world industrial context. Using a variety of advanced technologies that allow them to observe and understand their environment and make decisions based on their findings without the need for human intervention, they can effectively contribute to making our industry not only safer but also more productive.

If you would like to find out more about our autonomous robots for industrial inspections, check out our Technology page!